Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: KPEB-700-PB-20

Brand: ZHENGDING

Applicable Industries: express industry

Showroom Location: None

Condition: New

Machine Type: Bag Forming Machine

Material: Paper

Computerized: Yes

Brand Name: zhengding

Model Number: CAP-700

Dimension(L*W*H): 1900*2600*2300

Warranty: 1 Year

Key Selling Points: Easy To Operate

Marketing Type: New Product 2020, Other

Machinery Test Report: Provided

Video Outgoing-inspection: Provided

Warranty Of Core Components: 1 Year

Core Components: Motor

Max Speed: 70pcs/Min

Product Name: Kraft Paper Bubble Envelope Making Machine

Mechanical Execution Speed: 25-70 PCS/min

Maximum Bag-making Width (bag Height): 600mm (including envelope tongue)

Working Voltage: 380V50HZ, three-phase and four-wire

Maximum Bag Length (bag Width): 500mm

Effective Unwinding Width: 1250mm

Effective Unwinding Diameter: 1200mm

Mechanical Weight: 6000KG

Dimensions: 1900mm/2600mm/2300mm(L/W/H)

Power Backup: 30KW

Applicable Industry: Manufacturing Plant, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Status: New

Bag Material: Paper

Programming Control: Yes

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Easy To Operate, Flexible Manufacturing, Multifunctional, Long Service Life, Remote Control

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Bag Type: courier bag

Place Of Origin: Zhejiang, China

Voltage: 380V 50Hz

Weight: 6000 KG

Packaging: wooden pallet, stretch film package

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 5 Set/Sets per Month

Certificate: CE

Port: Ningbo,Shanghai

Payment Type: L/C,T/T

There are three kinds of environment protection bag:Ⅰ. paper courier bagsⅡ.paper document bagsⅢ.paper home use rubbish bag. Now we will mainly talk about the paper courier bag used in express industry:There are two kinds of paper courier bag:1.single layer Kraft paper courier bag with bottom gusset, 2.Kraft paper cushion courier bag, now let’s talk about these two kinds of paper courier bag.

(1)Bottom Gusset Bag Machine,we adopts Kraft paper which is over 85g/m² single layer, by part applying glue, folding and bottom gusset, online sticking easy tear line, heat pressing and sealing, tracking and cutting to form a perfect pure degrade environmentally courier bag used on express industry. It can instead the current gray and black plastic film courier bag, and it is the pure degrade environmentally courier bag in a real sense.

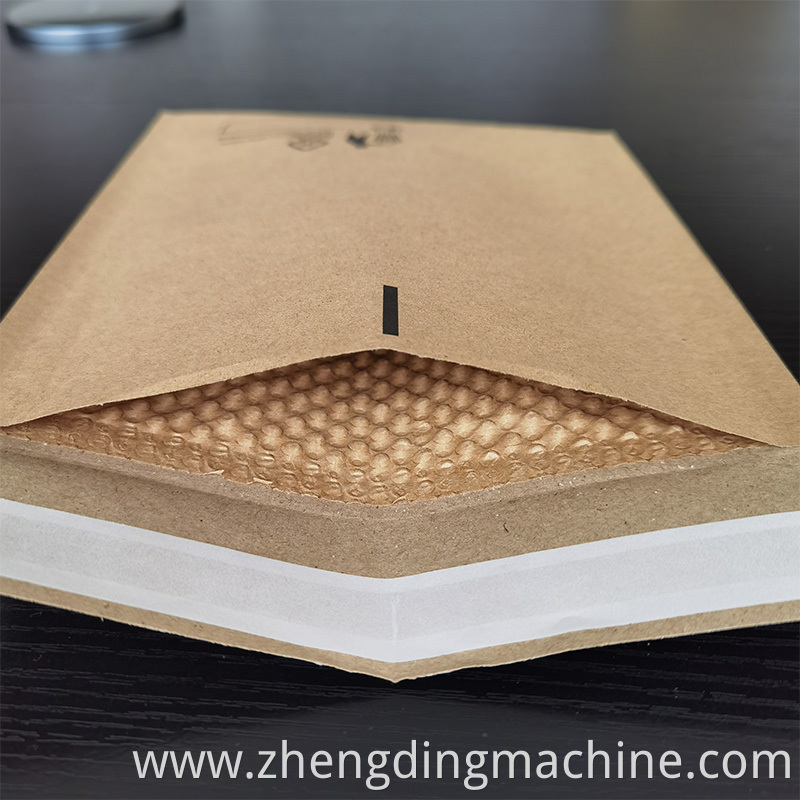

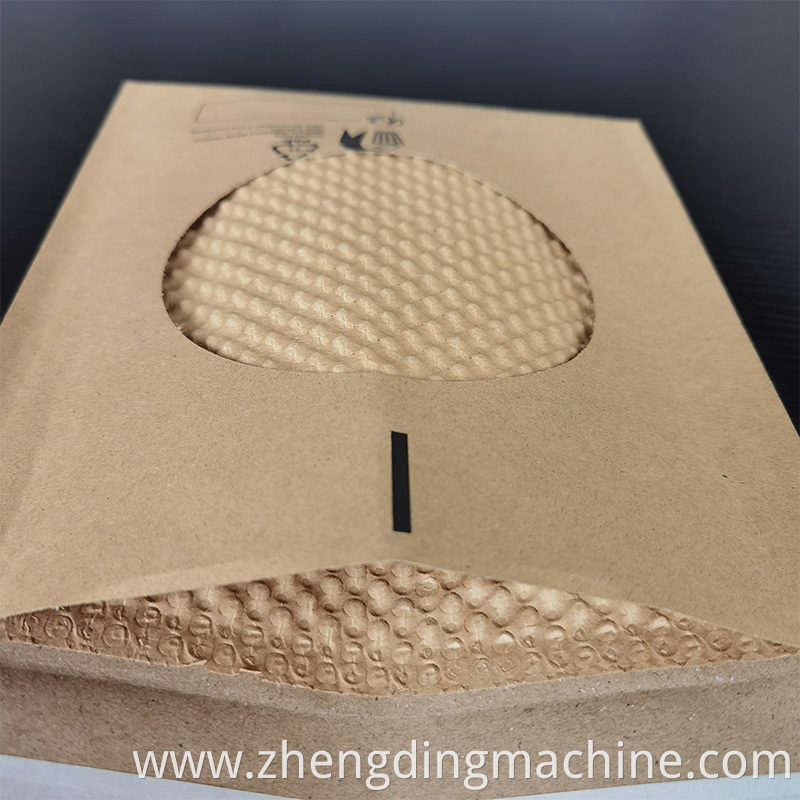

(2)Kraft paper cushion courier bag, the called cushion courier bag is that adding a layer of cushion material in the middle of two layers of Kraft paper. This two kinds of bags are divided into three kinds: honeycomb paper,pressed bubble paper and corrugated paper by the difference of the middle cushion layer. Because everyone knows well about the corrugated paper, we only talks about the honeycomb paper and pressed bubble paper cushion bag in the following.

1.Honeycomb Paper Envelope Machine:This kind of bag is made by sandwiching a layer of Kraft paper which stretching into honeycomb shape between two layers of Kraft paper, which is glued on the four sides to form an elastic packaging bag that is elastic if push by hand.

2.Paper Bubble Envelope Machine: This kind of bag is made by two or three layers material, it is also glued on the four sides to form a bag. Thus bag making equipment adopts online pressing bubble unit and inserting the material directly. We only need to put three rolls on the machine and then can finish the functions like pressing line and pressing bubbles, slitting and dispensing, part gluing, folding and pressing, and finally make a courier bag which is with pressed bubble cushion layer. The full procedure is finish by computer control at one time.This two kinds of paper environment friendly bag can instead the common plastic bubble film bag. They can be recycled and degraded one hundred percent and is the pure degrade environment friendly in a real sense.

And we also have:Honeycomb Paper Rolling Cutting Machine,Bubble Mailer Machine,,Corrugated Paper Envelope Machine

| product name: | Kraft Paper Bubble Envelope Making Machine |

| Max. speed: | 70pcs/min |

| Maximum bag length (bag width) | 500mm |

| Effective unwinding width | 1250mm |

| Material: | kraft paper |

| Effective unwinding diameter | 1200mm |

| Mechanical weight | 6000KG |

| Dimensions | 19000mm/2600mm/2300mm(L/W/H) |

| Power backup | 30KW |

Product Categories : Paper Bag Making Machine > Paper Bubble Envelope Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.