Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DNG-800F

Brand: ZHENGDING

Applicable Industries: Manufacturing Plant, Retail, Food & Beverage Shops

Condition: New

Machine Type: Bag Forming Machine

Material: Plastic

Computerized: Yes

Model Number: bubble mailer making machine

Dimension(L*W*H): 17000mm*2300mm*2300mm

Warranty: 1 Year

Key Selling Points: Remote Monitoring

After-sales Service Provided: Online Support, Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service

Suitable Bags: Poly bubble mailer and Kraft bubble mailer

Mechanical Speed: 40-110pcs/mi

Maximum Length Of Bag: 400mm

Machine Weight: 5500KGS

Overall Dimension: 17000mm*2300mm*2300mm(L*W*H)

Power Required: 45KW

Applicable Industry: Manufacturing Plant

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Status: New

Bag Material: Plastic

Programming Control: Yes

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Easy To Operate, Flexible Manufacturing, Multifunctional, Long Service Life, Remote Control

Marketing Type: New Product 2020, Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor

Bag Type: other

Place Of Origin: Zhejiang, China

Voltage: 380V 50Hz Three Phase Four wire, 380V 50Hz Three Phase Four wire

Weight: 6000kgs

Certification: CE

Brand Name: zhengding

Packaging: stretch film and wooden pallet or as customer's requirement.

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 10 Set/Sets per Month

Certificate: CE

Port: NINGBO PORT,SHANGHAI PORT

Payment Type: L/C,T/T

Incoterm: FOB

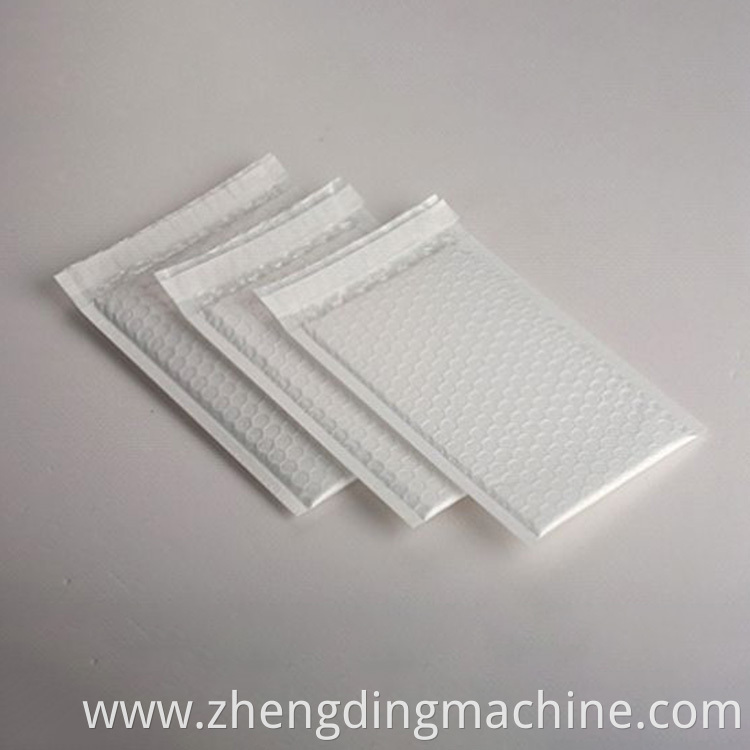

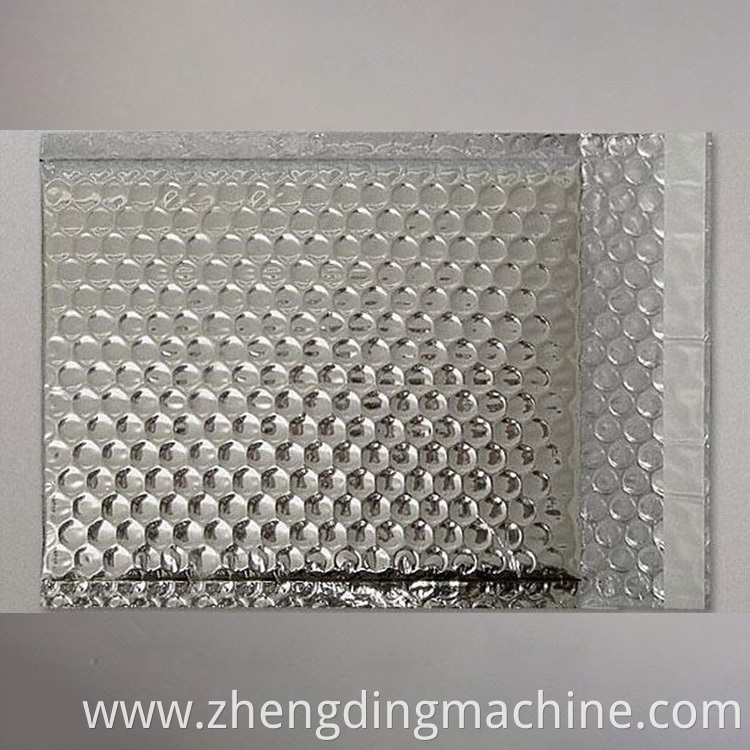

Bubble Mailer Machine is customized to make laminating Kraft and PE film bubble envelope in one line or double lines. And the machines are also suitable for making polythene film, aluminized film and pearl film bubble envelope. Method of making bags: First, make the laminating Kraft or PE film and bubble film together by heated laminating roller. Next fold the laminated material by folding devices. And then, seal the material by hot electric cross sealer. Finally cut the material and a standard laminated envelope is made. This machine is a specialized one with high quality and simple operation method .It adopts advanced motion control technology. And this machine is controlled by computer from unwinding to cutting. The envelopes made by this machine are good-looking and strong. We also have other paper devices: 1. Honeycomb Paper Envelope Machine: paper bags produced by it can replace bubble film bags and have a good buffering effect. 2. Paper Bubble Envelope Machine: paper bags produced by it can replace bubble film bags and have a good buffering effect. 3. Bottom Gusset Bag Machine: paper bags produced by it can replace gray and black film express bags, paper-plastic composite bags, and transparent paper can replace POPP clothing bags, hospital pill bags and so on. 4. Honeycomb Paper Rolling Cutting Machine: honeycomb paper can replace bubble film to package cosmetics, medicine bottles, circuit boards, electronic originals, etc., with good buffering effect. There is no plastic in these bags. They are all glued together. They are completely recycled pulp, which is environmentally friendly in the real sense.

| product name: | bubble mailer making machine |

| Suitable bags: | Poly bubble mailer and Kraft bubble mailer.(The machine can make laminating and folding two side seal bubble envelope.) |

| Mechanical speed: | 40-110pcs/mi |

| Max width of bag: | One line: 750mm (including the envelope flap) Double line: 350mm (including the envelope flap) |

| Maximum length of bag: | 400mm |

| Maximum width of unwinding: | paper or film: 1400mm bubble 1350mm |

| Maximum diameter of unwinding: | paper or film Φ800mm, bubble Φ1300mm |

| Machine weight: | 5500KGS |

| Overall Dimension: | 17000mm*2300mm*2300mm(L*W*H) |

| Power required: | 45KW |

| Voltage: | 380V 50Hz Three Phase Four wire |

| body: | Steel machine |

Q1:Do you accept customized?

A: Yes. The customer can tell your request, we have professional R&D team to customize machine for the customer.

Q2.What is the production cycle of the machine:

A: The production cycle is 30~60 days.

Q3.What is the warranty time?

A: The warranty time is 1 year after the buyer receive the machine. If any parts on the machine was broken(except vulnerable parts), we are responsible to repair or replace for free.

Q4. Does engineer available to serve machinery overseas?

A: Yes, engineer is available to install and training overseas for free for seven days. Our engineers are experienced and have long-term VISA for several countries.

Q5:What’s the after-sales service?

A.The seller will response and give solution in 48 hours if any urgent problems on machine.

B.The seller’s engineer can solve problems of machine by remote controlling if necessary( in warranty time freely, exceed warranty time, the seller should charge for the remote control.)

C.If problems can’t be solved by remote control, the seller will send one engineer to buyer’s factory for maintenance. The buyer should provide hotel, meal and round ticket for engineer and pay $ 100 per day as salary.

Product Categories : Paper Bag Making Machine > Bubble Mailer Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.